Company

PIZETA was born in 1982 from the idea of the founder Poli Renato as a family business and mechanical workshop

Company

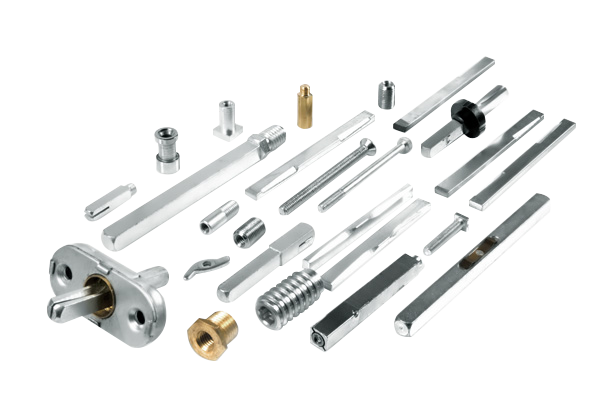

PIZETA was born in 1982 from the idea of the founder Poli Renato as a family business and mechanical workshop. In 1984, the first machines dedicated to the manufacture of handle pins were purchased, to date 90% of PI-ZETA's production is aimed at national and international handle manufacturers, through dedicated and cutting-edge machinery.

History

40 years of family business history.

Values

Every day we believe in our values and transmit them to customers, suppliers and cooperators.

Machines

Innovation and technology through the machines we have

Environment

We care about our planet as much as we care about our quality

Services

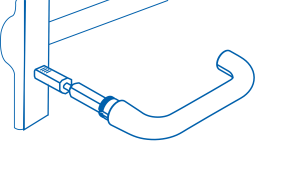

PIZETA offers its customers a wide range of items in the catalog and the possibility of producing a large variety of customized models based on customer specifications. The owners of the company personally take care of commercial and technical relationships with customers, making their decades of experience available for free consultations aimed at finding the best and personalized solution for each problem or request, thus developing ad hoc estimates for each customer.

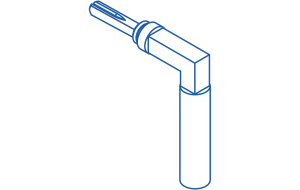

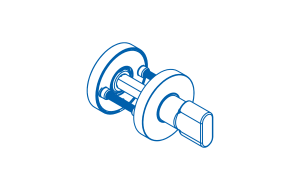

Production of spindles with heat treatment (different hardnesses).

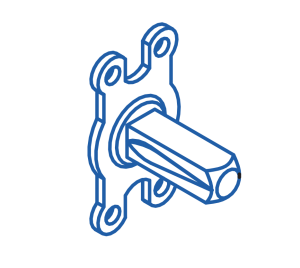

Production of products according to customer specifications or drawings.

Customization of the product by engraving.

Knowledge

Commercial presence and technical product know-how for each market.

Process

The customer, the product and the manufacture process are at the centre of all our services.

Innovation

Industry 4.0 Research and development for product and process improvement.

Quality and Technique

Quality is our fixed idea: focusing on attention, care, improvement, maintenance and motivation enables us to reach a high quality every day.

Certifications

PIZETA is ISO 9001: 2015 certified by the TUV Italy certification body.

Materials

A careful choice and selection of materials and suppliers.

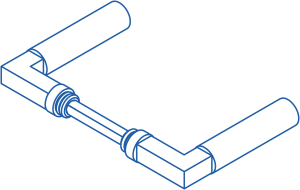

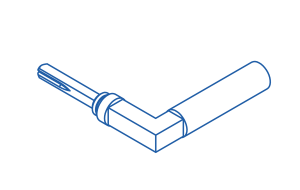

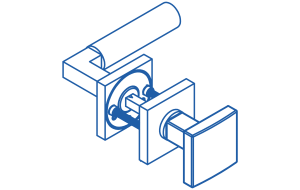

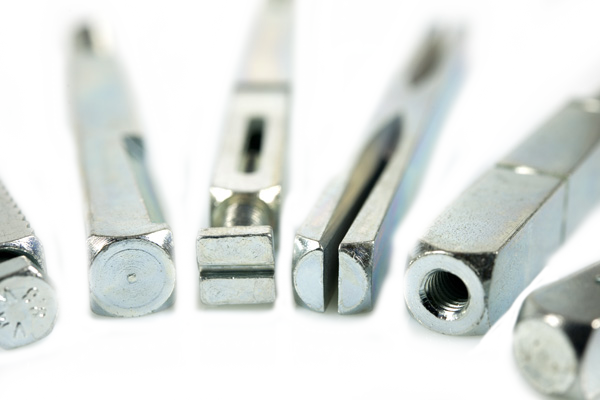

PRODUCTS

High quality spindles and accessories for handles. Thanks to our history and our know how we design and produce high quality spindles and accessories for every kind of handle to meet any customer request.

Product news

Research and development for continuous product improvement and the creation of new solutions

NEWS